WHAT ARE HEAT RESISTANT BEARINGS?

Heat resistant and high temperature bearings are manufactured specially for extreme heat environments and applications. Heat resistant, stainless steel bearings utilize specialized lubricants, like grease, in order to withstand higher temperatures. While lubrication options with other manufacturers utilize sintered alloy or solid molybdenum disulfide (MoS2) lubrication, grease-filled bearings with fluorine grease can be used to withstand high heat.

SMT manufactures AISI stainless steel, heat resistant bearings with fluorine grease that are resistant up to 440℃ (824℉) for various applications. These bearings are ideal for a variety of different industry applications including high temperature areas, drying equipment, vacuum apparatus, and furnace, oven, or heater devices.

KEY BENEFITS OF SMT STAINLESS STEEL HEAT RESISTANT BEARINGS

Increased Heat Resistance

SMT stainless steel heat resistant bearings offer increased heat resistance when compared to other bearings in the market. The SMT bearings are operable up to 482℉, except for the sealed type which can withstand temperatures up to 392°F.

The AISI 440C stainless steel that SMT uses for these heat resistance bearings has been shown to have a lower hardness decrease ratio and small dimension changes when compared to SAE 52100 bearing steel in extreme temperatures. AISI 440C has also proved to have superior oxidation resistance and overall durability in higher temperatures as well.

Increased Lifetime and Durability

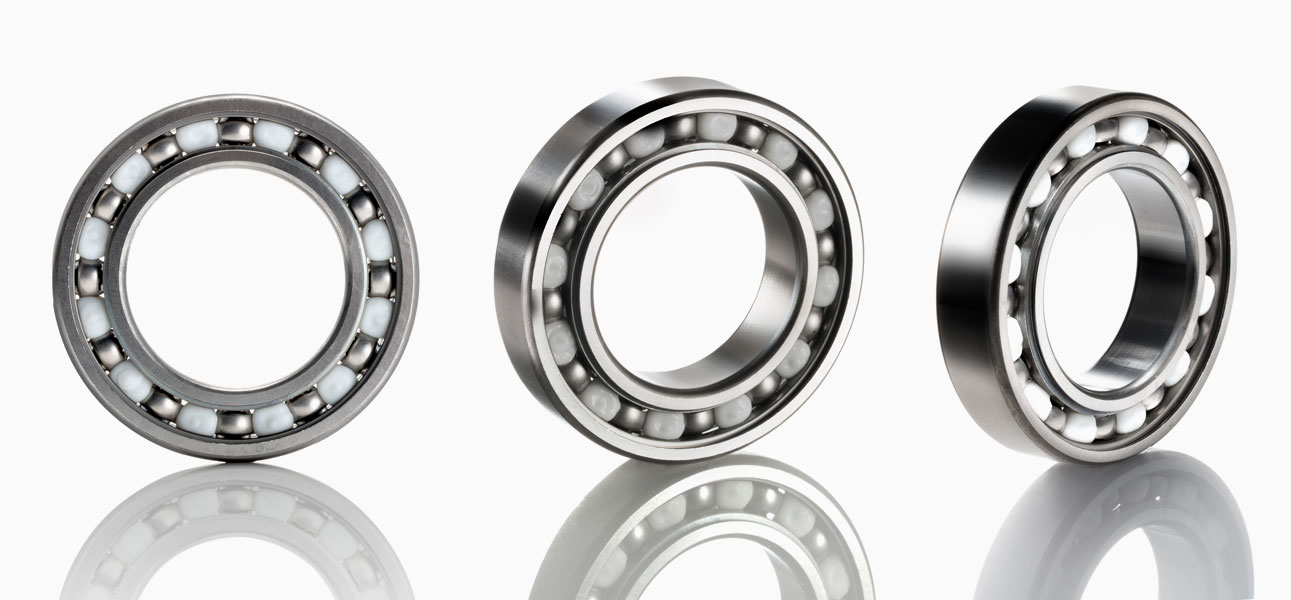

SMT’s unique stainless steel heat resistant bearings incorporate ceramic balls into the part, extending the lifetime, performance, and durability. The ceramic balls help to lower the heat generation, thereby extending the grease life which also decreases the running cost of the part by extending its usability over time.

The inclusion of ceramic balls in heat resistant bearings have several benefits including:

- Lowering centrifugal force

- Small variation of internal clearance

- Superior abrasion resistance

- Reduced friction by high rigidity

- Maintaining high load capacity in increased temperatures

- Preventing electric corrosion

Ritbearing provides customers with the best bearings to meet every industry application need. With SMT stainless steel heat resistant bearings, you can lower your overall costs while extending the bearing lifespan. SMT’s heat resistance bearings are superior in design due to the use of ceramic balls which increase temperature resistance and durability beyond the industry standards.

Want to learn more about SMT stainless steel heat resistant bearings? Contact us today!